Metallurgists face a variety of challenges in their profession, driven by technological advancements, economic factors, and environmental concerns. These challenges span across different stages of the metallurgical process, from material selection to production and sustainability.

Material Selection and Development

- Advancement in Materials: The continuous development of new alloys, composites, and advanced materials requires metallurgists to stay updated and proficient in understanding their properties and applications.

- Complex Material Systems: Modern engineering applications often involve complex material systems that require careful selection and integration to ensure optimal performance and reliability.

Production and Processing

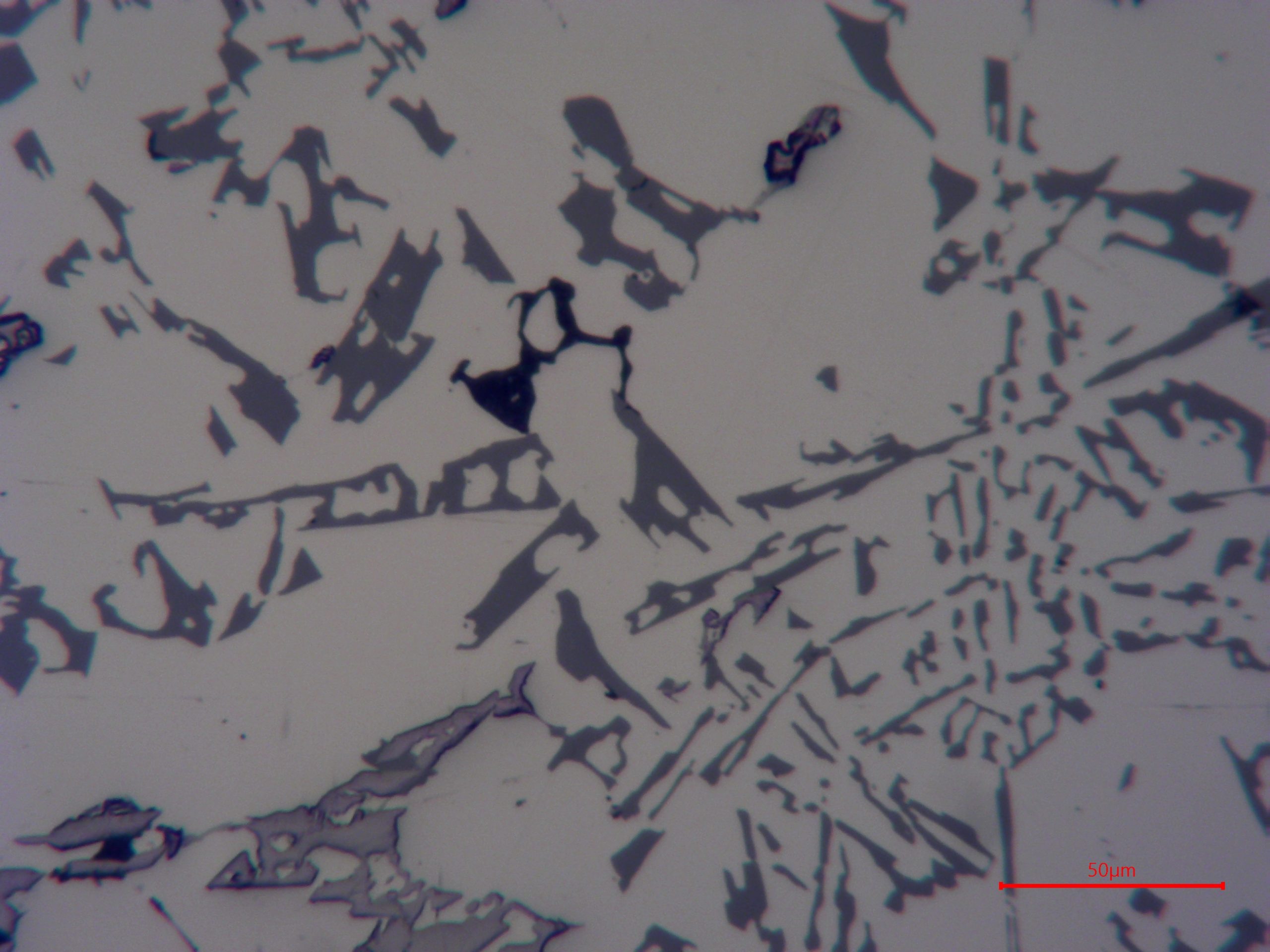

- Process Optimization: Improving the efficiency and productivity of metallurgical processes while maintaining quality is a constant challenge. This involves optimizing parameters such as temperature, pressure, and processing time.

- Quality Control: Ensuring consistent quality in metallurgical products requires advanced testing and inspection techniques. Metallurgists must implement and manage quality control systems to meet stringent industry standards.

Sustainability and Environmental Concerns

- Environmental Regulations: Stricter environmental regulations require metallurgists to minimize the environmental impact of metallurgical processes. This includes reducing emissions, waste generation, and energy consumption.

- Recycling and Resource Efficiency: Developing efficient recycling processes and promoting resource efficiency are crucial for sustainable metallurgy. Metallurgists need to find innovative ways to recover and reuse valuable materials from waste streams

Technological and Digital Transformation

- Adoption of New Technologies: Integrating new technologies such as AI, machine learning, and data analytics into metallurgical processes can be challenging. Metallurgists need to adapt to these technologies to improve efficiency and decision-making.

- Digitalization of Processes: Implementing digital solutions for process monitoring, simulation, and optimization requires significant investment and expertise. Metallurgists must embrace digitalization to stay competitive in the industry.

Economic and Market Factors

- Global Competition: Intense global competition requires metallurgists to continuously improve their processes and products to remain competitive. This includes reducing costs, improving quality, and developing innovative solutions.

- Market Volatility: Fluctuations in raw material prices and market demand can impact the profitability of metallurgical operations. Metallurgists need to be agile and adapt to changing market conditions.