Bridging Innovation and Reliability

Mechanical testing, a cornerstone of engineering and materials science, has traditionally relied on hands-on experimentation and expert analysis to evaluate material properties, structural integrity, and product performance. As artificial intelligence (AI) revolutionizes countless industries, its integration into mechanical testing promises unprecedented efficiency and insight. However, a central question remains: Can we truly trust AI-generated results in this critical field?

The Promise of AI in Mechanical Testing

AI algorithms, especially those leveraging machine learning and deep learning, excel at analyzing vast datasets, identifying subtle patterns, and predicting outcomes beyond human intuition. In mechanical testing, AI can:

- Automate data collection and processing from sensors and imaging devices,

- Detect anomalies or defects with greater accuracy,

- Predict material behavior under stress or fatigue, and

- Optimize testing protocols to save time and reduce costs.

These capabilities offer tremendous advantages, potentially transforming development cycles and ensuring safer, more reliable products.

The Challenge of Trust

Despite these benefits, skepticism about AI’s reliability persists. Mechanical testing results often inform safety-critical decisions—whether in aerospace, automotive, construction, or medical device sectors—and errors can have severe consequences. Trust hinges on several key factors:

- Transparency of AI Models: Many AI systems, particularly deep neural networks, operate as “black boxes,” making it difficult to understand how specific conclusions are reached. Without clear interpretability, engineers may hesitate to rely on these insights.

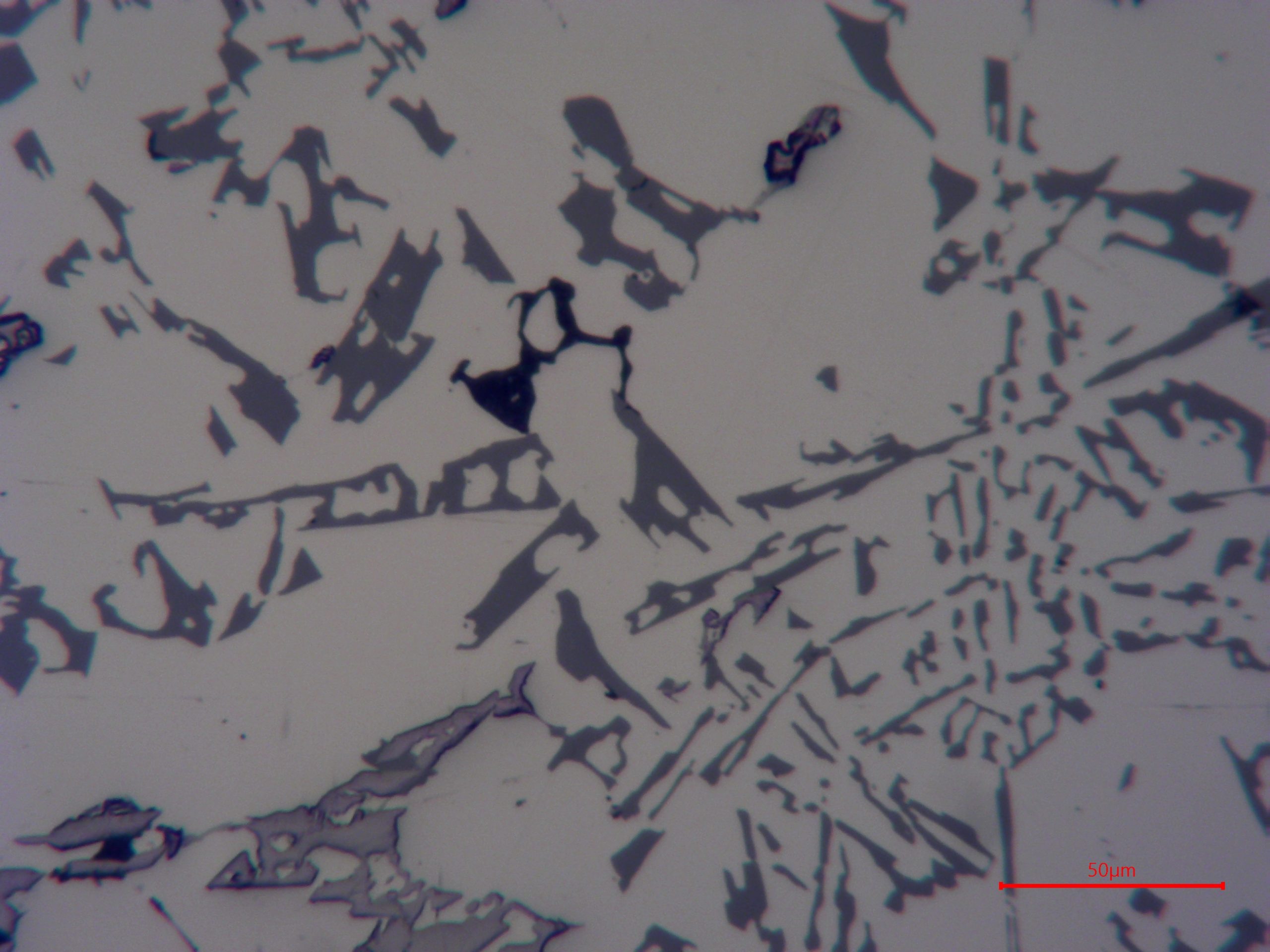

- Quality and Diversity of Training Data: AI’s accuracy depends heavily on the data it learns from. If training datasets lack representative samples of materials, loading conditions, or failure modes, predictions may be biased or incomplete.

- Validation Against Established Standards: AI-driven results must be rigorously validated against traditional mechanical testing methods and industry standards. Cross-verification builds confidence and highlights situations where AI excels or struggles.

- Robustness to Variability: Mechanical testing environments can be highly variable. AI systems should demonstrate consistent performance across different machines, operators, and environmental conditions.

Building a Framework for Trust

To harness AI’s potential while ensuring dependable results, the mechanical testing community can adopt several best practices:

- Explainable AI (XAI): Develop models that provide interpretable outputs, enabling engineers to verify AI reasoning and incorporate domain expertise.

- Comprehensive Dataset Curation: Collaborate across industries to assemble diverse, high-quality datasets that capture a wide range of scenarios and materials.

- Hybrid Approaches: Combine AI predictions with traditional testing and expert review, using AI as an augmentative tool rather than a sole decision-maker.

- Continuous Monitoring and Updating: Implement feedback loops where AI models are regularly updated with new data and testing outcomes to maintain accuracy over time.

Looking Ahead

As AI continues to mature, its role in mechanical testing will undoubtedly expand. Trust is not a given but a goal achieved through transparency, rigorous validation, and thoughtful integration. By fostering collaboration between AI developers, mechanical engineers, and standardization bodies, we can build systems that not only accelerate innovation but also uphold the highest standards of safety and reliability.

In embracing AI for mechanical testing, we stand at the frontier of a new era—one where human expertise and artificial intelligence combine to push the boundaries of what materials and machines can achieve, with trust as the foundation.