The next generation of materials beyond superalloys aims to overcome the limitations of nickel-based superalloys, which have been the standard for high-temperature applications for decades. These materials are designed to withstand higher temperatures and offer improved performance in extreme conditions. Research focuses on cobalt-based alloys, high-entropy alloys, metal-ceramic composites, and copper alloys

Research and Development

- Cobalt-Based Alloys: Cobalt (Co) based superalloys are under development as potential replacements for nickel-based superalloys, particularly where high-temperature creep resistance is needed.

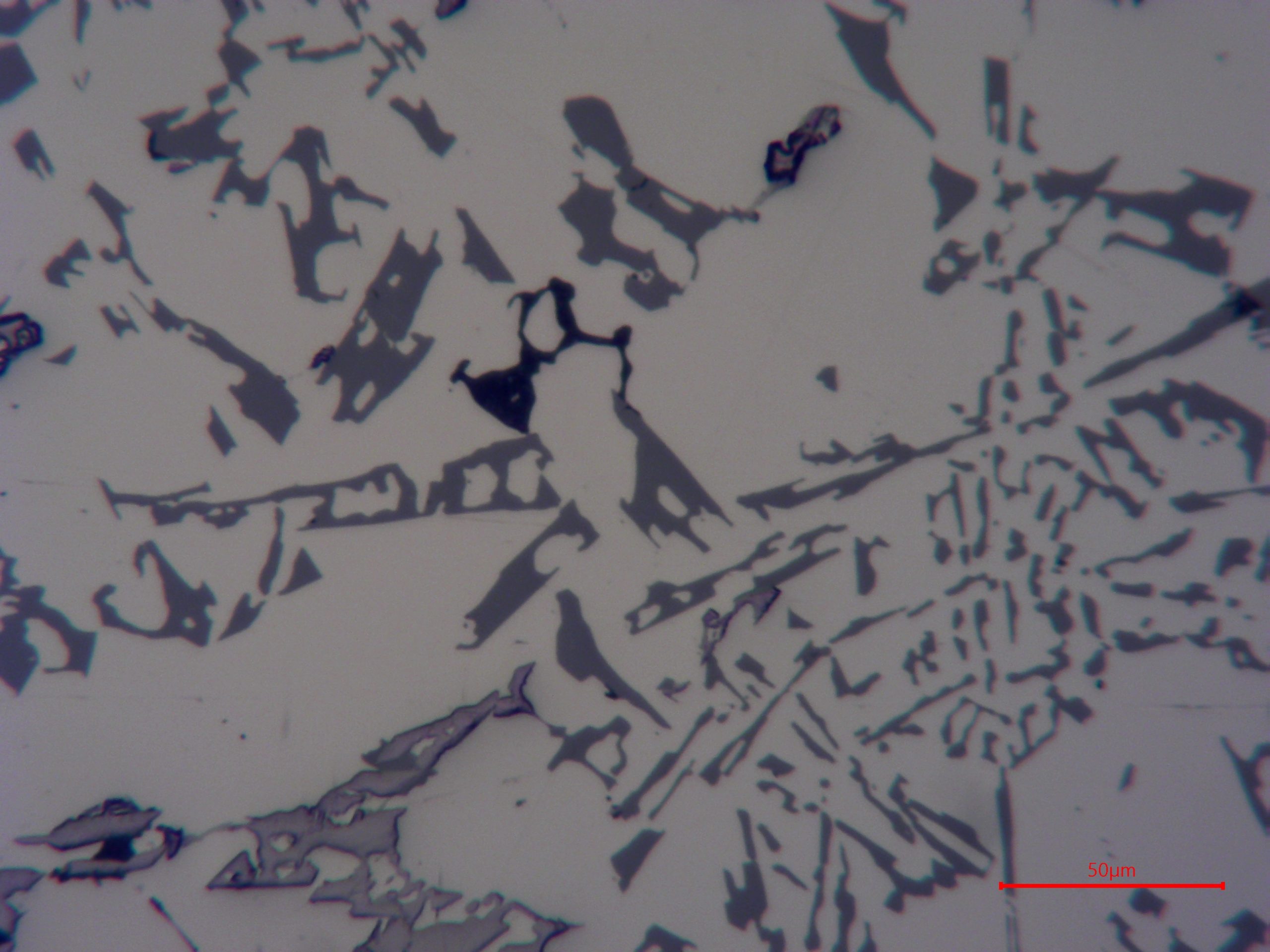

- High-Entropy Alloys (HEAs): HEAs, composed of multiple principal elements, are being explored for their unique properties, including enhanced catalytic activity, superior stability, and tunable electronic structures. Refractory HEAs (RHEAs), composed of refractory metals like molybdenum, titanium, and tungsten, show promise as replacements for nickel-based superalloys in high-temperature applications.

- Metal-ceramic composites: Metal-ceramic composites combine metals with ceramic materials to achieve high-temperature strength and oxidation resistance.

- Copper Alloys: Researchers are also developing copper-based materials with superalloy-like strength by merging copper’s conductivity with the resilience of nickel-based superalloys. These materials are suited for heat exchangers and thermal management system

Applications

These next-generation materials are being developed for use in a variety of advanced applications:

- Aerospace: For turbine engines and other high-temperature components in aircraft and rockets.

- Defense: In advanced propulsion systems and thermal management solutions for missiles and hypersonic technologies.

- Energy: For high-temperature solid oxide electrolyzer cells (SOECs) and other electrochemical applications.

- Automotive: In high-performance engines.

Challenges and Future Directions

The development of materials beyond superalloys involves overcoming challenges such as achieving the necessary creep resistance, preventing oxidation at high temperatures, and scaling up production. Future research will likely focus on refining alloy compositions, optimizing processing techniques, and exploring novel material combinations to meet the demands of increasingly extreme operating environments