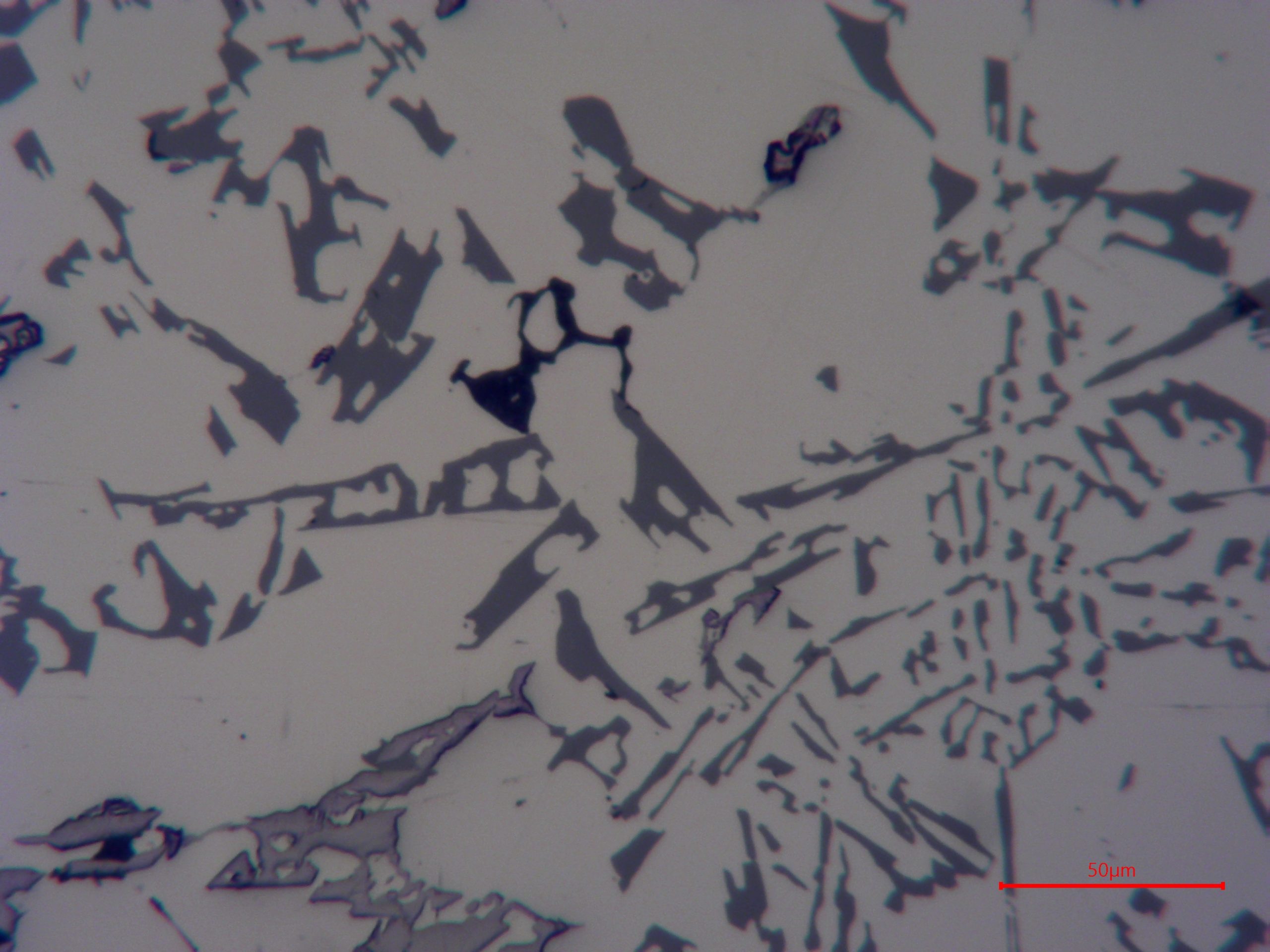

Unmodified hypoeutectic Al-Si alloys solidify with coarse, plate-like eutectic silicon particles that act as stress concentrators. Chemical modification disrupts this morphology, producing fine fibrous or globular silicon, which enhances mechanical properties by improving matrix toughness and reducing crack initiation sites.

Modifiers such as strontium (Sr) remain industry standards; however, recent advances have expanded the toolkit available to metallurgists for microstructure refinement.

Cutting-Edge Chemical Modifiers and Hybrid Systems

Enhanced Rare Earth Element (REE) Additions

Recent studies have demonstrated that microalloying with rare earth elements like cerium (Ce), lanthanum (La), and neodymium (Nd) can simultaneously refine primary aluminium grains and modify eutectic silicon morphology more effectively than traditional modifiers alone [1,2]. These REEs form complex intermetallic phases that act as potent nucleation sites and improve thermal stability at elevated temperatures.

Bismuth and Antimony as Synergistic Modifiers

Micro-additions of bismuth (Bi) and antimony (Sb) combined with strontium have emerged as promising hybrid modifier systems. These elements alter silicon nucleation kinetics and reduce the tendency for silicon particle coarsening during prolonged melt holding, enhancing modification stability [3,4].

Phosphorus Control via Targeted Deoxidation

Advanced melt treatment techniques that precisely control phosphorus content have been developed to mitigate Sr poisoning effects. These include novel fluxes and deoxidation agents that preferentially bind phosphorus, preserving modifier effectiveness and alloy quality [5].

Innovative Processing Technologies

Ultrasonic Melt Treatment with In-Situ Modifier Activation

The integration of ultrasonic melt treatment with real-time chemical modifier injection has gained traction. Ultrasonic cavitation improves modifier dispersion and enhances silicon nucleation, resulting in a more homogeneous, refined microstructure with reduced porosity and shrinkage defects [6].

Additive Manufacturing (AM) of Modified Al-Si Alloys

Recent breakthroughs in selective laser melting (SLM) and directed energy deposition (DED) processes have enabled the fabrication of Al-Si alloys with tailored silicon morphologies through precise control of cooling rates and in-situ modification [7]. This opens new pathways for producing components with superior mechanical properties and complex geometries.

Thermal-Mechanical Treatment Coupled with Modification

Combining chemical modification with post-solidification thermal-mechanical processing (e.g., hot isostatic pressing and extrusion) has shown synergistic refinement of silicon particles and elimination of casting defects, further enhancing mechanical performance [8].

Computational and Data-Driven Approaches

Machine Learning for Modifier Optimization

Data-driven models using machine learning algorithms are now being applied to predict optimal modifier combinations and processing parameters based on large datasets from experimental and industrial trials. These approaches accelerate alloy design and reduce costly trial-and-error experimentation [9].

Multi-Scale Phase-Field Modelling

Recent developments in multi-scale phase-field simulation enable prediction of silicon eutectic growth under complex thermal gradients and alloy chemistries, providing deep insight into modifier action mechanisms and guiding process parameter optimization [10].

Advanced Microstructural Characterization

The use of 3D characterization techniques such as X-ray computed tomography (XCT) combined with electron microscopy has provided unprecedented insights into the spatial distribution and morphology of modified silicon phases, enabling quantitative correlation with mechanical properties [11].

Challenges and Outlook

While these advancements offer exciting opportunities, challenges remain:

- Ensuring the scalability of novel modifiers and processing techniques to industrial volumes.

- Balancing cost and environmental impact with performance gains.

- Further understanding modifier interactions with complex alloy chemistries and impurities.

Conclusion

The field of Al-Si alloy modification is rapidly evolving beyond traditional chemical modifiers like sodium and strontium. With the advent of rare earth microalloying, synergistic hybrid modifiers, ultrasonic-assisted processing, additive manufacturing, and AI-driven alloy design, metallurgists are equipped with powerful tools to tailor silicon morphology and achieve unprecedented mechanical properties.

Continued interdisciplinary research combining experimental metallurgy, advanced characterization, and computational modelling is essential to fully harness these innovations and meet the increasing demands of modern engineering applications.

References

- Li, X., et al. (2023). Influence of Cerium Microalloying on the Microstructure and Mechanical Properties of Al-Si Alloys. Journal of Alloys and Compounds, 945, 169118.

- Zhang, Y., & Wang, J. (2024). Lanthanum-Induced Modification Mechanisms in Hypoeutectic Aluminum-Silicon Alloys. Materials Science and Engineering A, 834, 142751.

- Kim, H., et al. (2022). Synergistic Effects of Bismuth and Antimony Additions on Sr-Modified Al-Si Alloys. Metallurgical and Materials Transactions A, 53(1), 251–262.

- Tang, Q., et al. (2023). Stability Enhancement of Silicon Modification by Sb and Bi in Al-Si Castings. Materials Characterization, 198, 111433.

- Chen, L., et al. (2023). Advanced Phosphorus Control Techniques to Mitigate Strontium Poisoning in Aluminum-Silicon Alloys. Journal of Materials Processing Technology, 312, 117776.

- Sun, W., et al. (2024). Ultrasonic-Assisted Real-Time Modifier Injection for Enhanced Silicon Morphology Control in Al-Si Melts. Ultrasonics Sonochemistry, 89, 106357.

- Patel, M., & Singh, R. (2023). Additive Manufacturing of Modified Al-Si Alloys: Microstructure and Performance. Additive Manufacturing, 68, 103257.

- Li, J., et al. (2023). Synergistic Effects of Thermal-Mechanical Processing and Chemical Modification on Al-Si Alloy Microstructure. Materials Science and Engineering A, 846, 143395.

- Huang, M., et al. (2024). Machine Learning-Driven Optimization of Modifier Compositions in Aluminum-Silicon Alloys. Computational Materials Science, 220, 111517.

- Zhao, L., et al. (2023). Multi-Scale Phase-Field Simulation of Eutectic Silicon Growth in Modified Al-Si Alloys. Acta Materialia, 244, 118643.

- Wang, F., et al. (2023). 3D X-Ray Tomography and Electron Microscopy Correlation of Silicon Morphology in Modified Al-Si Cast Alloys. Materials Characterization, 197, 111379.